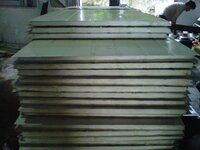

Wall Puf Panel

Product Details:

- Height As per project specification

- Features Fire Resistant, High Thermal Insulation

- Roof Material PUF with PPGI or Stainless Steel Sheet

- Technics High Pressure Injection Molding

- Surface Treatment Color Coated/Galvanized

- Usage & Applications Cold Storages, Warehouses, Clean Rooms, Industrial Buildings

- Material Polyurethane Foam (PUF), Pre-painted Galvanized Iron (PPGI), Stainless Steel Sheet

- Click to View more

X

Wall Puf Panel Price And Quantity

- 100 , , Square Meter

Wall Puf Panel Product Specifications

- Customized as per requirement

- Rectangular

- Wall Panel

- 1.2 meters (standard)

- As per project specification

- 0.024 W/mK

- Wall Puf Panel

- 40 mm to 150 mm

- Plain/Smooth Finish

- PUF Core with Metal Sheets

- Fire Resistant, High Thermal Insulation

- Up to 12 meters

- PUF with PPGI or Stainless Steel Sheet

- Polyurethane Foam (PUF), Pre-painted Galvanized Iron (PPGI), Stainless Steel Sheet

- Cold Storages, Warehouses, Clean Rooms, Industrial Buildings

- High Pressure Injection Molding

- Color Coated/Galvanized

Wall Puf Panel Trade Information

- 500 , , Square Meter Per Month

- 25 Days

- All India

- ISO 9001:2015

Product Description

Wall Puf Panel

Wall panel provide both side 0.5 mm thick ppgi sheet with nominal grooves Roof panel provide one side 0.5 mm thick ppgi sheet with nominal grooves and one side 0.5 mm thick ppgi sheet with trapezoidal grooves crest 30mm

Product details

|

Usage |

For Roof |

|

Size |

Up-to 8 meter |

|

Thickness |

Available 40, 50, 60, 80, 100, 125, 150 mm |

Superior Insulation and Safety

Designed with high-density, CFC-free PUF and double metal cladding, Wall PUF Panels deliver top-notch thermal insulation and excellent acoustic dampening. Their fire rating, as per IS and ASTM standards, provides enhanced safety for demanding applications. The closed-cell structure virtually eliminates water absorption, further extending the panels durability and effectiveness.

Quick and Modular Installation

Featuring a tongue and groove interlocking edge profile, these panels allow for fast, modular assembly, reducing project timelines and labor costs. This system ensures tight joints for optimal insulation and minimal thermal bridging, making it easy to adapt to varied building layouts and site requirements.

Customizable for Diverse Applications

Available in thicknesses from 40 mm to 150 mm, and up to 12 meters long, Wall PUF Panels fit diverse needs. Choose from standard colors like white, blue, or grey, or customize shades to match project aesthetics. Suitable for cold storages, clean rooms, warehouses, and industrial buildings, these panels stand up to extreme temperatures and environmental challenges.

FAQs of Wall Puf Panel:

Q: How are Wall PUF Panels installed, and what is the typical installation process?

A: Wall PUF Panels utilize a tongue and groove interlocking system that ensures fast and secure modular installation. The lightweight panels are aligned and locked into place, minimizing gaps and enabling rapid project completion without the need for extensive specialized labor.Q: What materials are used in the construction of Wall PUF Panels and what makes them unique?

A: Wall PUF Panels feature a CFC-free, closed-cell polyurethane foam (PUF) core sandwiched between pre-painted galvanized iron (PPGI) or stainless steel sheets, offering superior insulation, corrosion, and moisture resistance. The combination creates panels that are durable, fire-resistant, and highly energy efficient.Q: When are Wall PUF Panels most beneficial for building projects?

A: These panels are ideal for environments requiring strict temperature or hygiene control, such as cold storages, clean rooms, and warehouses. Their excellent thermal and acoustic properties, combined with fire resistance, make them a smart choice for industrial or commercial facilities demanding safety and performance.Q: Where can Wall PUF Panels be customized to suit specific project requirements?

A: Panels can be customized by working directly with fabricators, manufacturers, or suppliers in India. They are available in various thicknesses (40150 mm), lengths (up to 12 meters), widths, and surface colors, providing flexibility to tailor panels according to structural and aesthetic needs.Q: What is the process behind manufacturing Wall PUF Panels?

A: Wall PUF Panels are manufactured using high-pressure injection molding, ensuring uniform core density and structural integrity. The closed-cell PUF is injected between metal sheets, which are then bonded together, resulting in panels with consistent quality and performance.Q: How do Wall PUF Panels benefit building owners and occupants?

A: Owners and occupants benefit from significant energy savings due to high thermal insulation, increased fire and acoustic safety, minimal maintenance, and accelerated construction schedules. The panels resistance to moisture, corrosion, and environmental extremes translates to a longer-lasting, low-hassle building envelope.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email