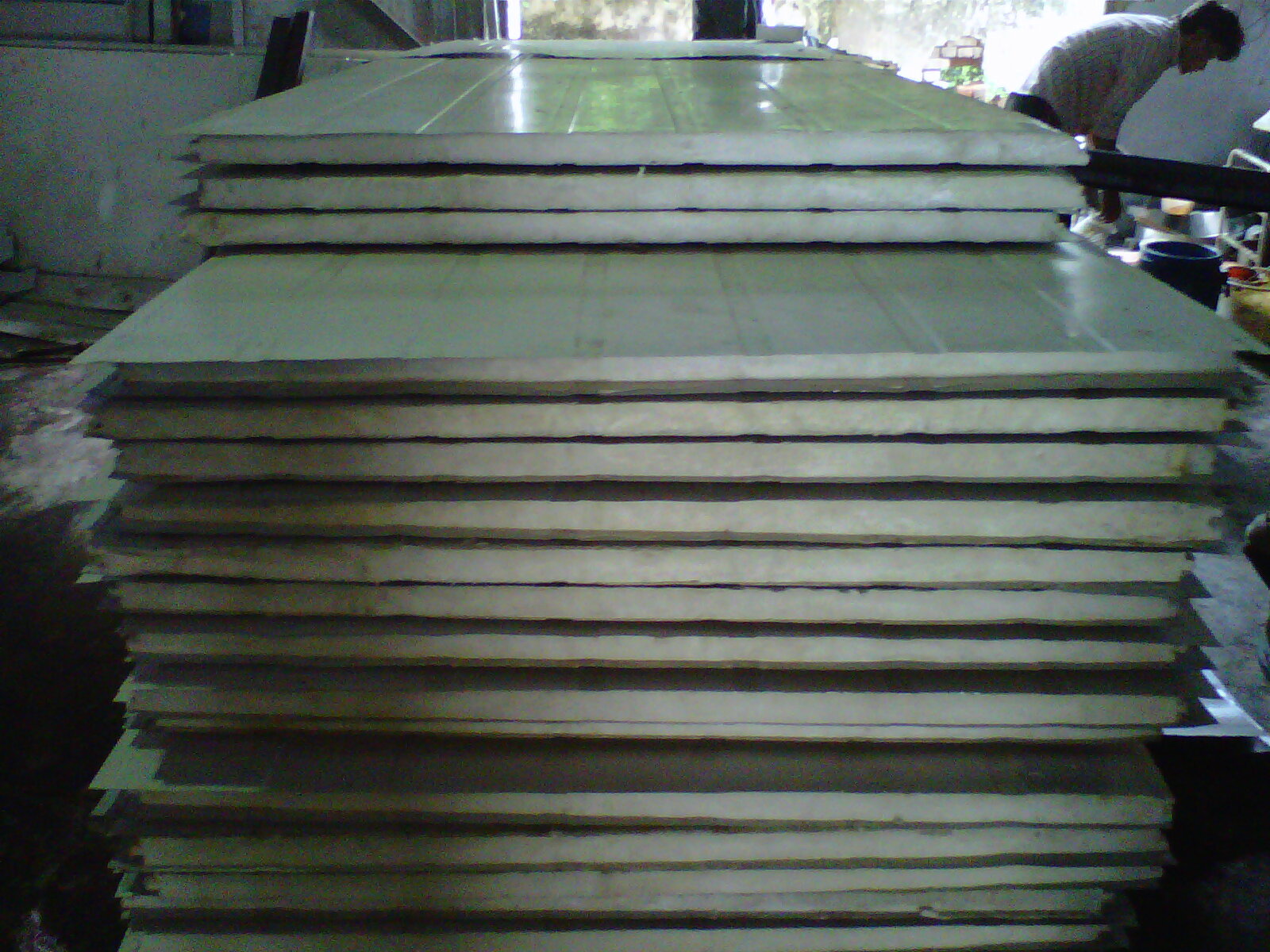

Polyurethane Sandwich Panels

Product Details:

- Surface Treatment PE/PVDF Coated

- Installation Guideline Fix panels on pre-fabricated steel structure with self-drilling screws and sealant at joints

- Density 40 Kilogram per cubic meter (kg/m3)

- Size Standard and custom lengths up to 12m

- Feature Lightweight, High Insulation, Fire Resistant

- Coating Type Polyester/Polyurethane (PE/PVDF)

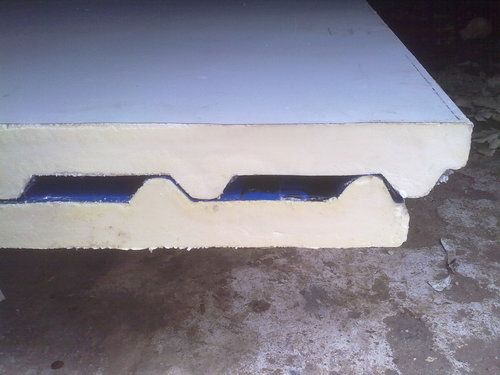

- Layer Three layers (Top PPGI Sheet - Polyurethane Core - Bottom PPGI Sheet)

- Click to View more

Polyurethane Sandwich Panels Product Specifications

- Polyester/Polyurethane (PE/PVDF)

- PPGI Sheet and Polyurethane Foam

- 0.021-0.023 W/(mK)

- White, Blue, Grey, or as required

- Three layers (Top PPGI Sheet - Polyurethane Core - Bottom PPGI Sheet)

- For Wall and Roof

- 1000 mm (standard), Customizable

- -40C to +110C

- PE/PVDF Coated

- 0.021-0.023 W/(mK)

- 40 Kilogram per cubic meter (kg/m3)

- Fix panels on pre-fabricated steel structure with self-drilling screws and sealant at joints

- 200 kPa

- Insulated Sandwich Panel

- Lightweight, High Insulation, Fire Resistant

- 30-200 Millimeter (mm)

- Standard and custom lengths up to 12m

Polyurethane Sandwich Panels Trade Information

- 500 Per Month

- All India

- ISO 9001:2015

Product Description

We have gained specialization in presenting a vast array of strategically structured Polyurethane Sandwich Panels. They are utilized widely in the construction industries for surface cladding applications. These panels can be effortlessly applied owing to their light weight. The sandwich panels are extremely last longing and deserves to be the first choice of every customer in the global market. They are coil coated properly to protect them from corrosion and rust. The Polyurethane Sandwich Panels can be purchased by buyers in multiple characteristics to adequately fulfill requirements of clients. They have a solid structure that allow them to bear excess pressure without any wear and tear.

Product details

|

Color |

White |

|

Application |

Wall & Roof |

|

Material |

Polyurethane |

Superior Fire and Thermal Performance

Our panels achieve fire ratings of B2/B3 with a flame spread index under 25, and thermal conductivity as low as 0.021 W/(mK). This ensures robust thermal insulation, safety, and energy efficiency for diverse building requirements while meeting regulatory standards for fire safety and heat control.

Durability Meets Easy Installation

Polyurethane Sandwich Panels are engineered for resilience with a service life exceeding 25 years and compressive strengths above 150 kPa. Their edge treatment features tongue and groove interlocking systems, allowing rapid assembly with self-drilling screws and sealants, reducing labor costs and installation time.

Customizable to Your Project Needs

Available in a range of thicknesses (30200 mm), colors (white, blue, grey, and more), and metal skin gauges (0.35 mm0.60 mm), these panels can be tailored to the specific requirements of your construction project, ensuring optimal performance in various climates and environments throughout India.

FAQs of Polyurethane Sandwich Panels:

Q: How are Polyurethane Sandwich Panels installed?

A: Installation is straightforward: panels are fixed on a pre-fabricated steel framework using self-drilling screws and sealant applied at the joints. The tongue and groove or camlock edge treatment ensures tight interlocking and secure alignment, minimizing thermal bridges and improving airtightness.Q: What applications are these panels suitable for?

A: These panels are designed for use in both wall and roof systems across commercial, industrial, and residential buildings. Their high insulation, fire resistance, and durability make them ideal for cold storage, warehouses, manufacturing facilities, and energy-efficient homes.Q: When should I choose a custom thickness or size for my panels?

A: Opt for custom thickness (30200 mm) or length (up to 12 meters) when your project requires specific insulation values or structural parameters. Custom sizes cater to unique design or load requirements, optimizing energy performance and material usage.Q: Where can these panels be installed effectively?

A: Polyurethane Sandwich Panels can be installed in a variety of locations, including urban and coastal areas, thanks to their corrosion and chemical resistance. Their environmental durability suits factories, office buildings, residential complexes, or any site requiring robust insulation solutions.Q: What is the benefit of the tongue and groove or camlock joint system?

A: The tongue and groove or camlock joint system enhances the ease and speed of installation, ensures precise alignment, and creates a tight seal that improves both thermal and sound insulation by minimizing air and water ingress.Q: How do these panels contribute to energy efficiency?

A: The low thermal conductivity (0.0210.023 W/(mK)) and closed-cell polyurethane foam core drastically reduce heat exchange, maintaining interior temperature and significantly lowering heating and cooling energy requirements, which helps to reduce operational costs over time.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+